Pil Sensoren: measuring distance with ultrasone sensor

Do you want to measure distance with an ultrasone sensor? Be sure to avoid technical problems when integrating the sensor in your machine. And how do you ensure reliable measurements in harsh environments, such as those containing dust and moisture? These are common substances, certainly in agricultural and industrial applications. Integrating a distance sensor requires specific knowledge of production and R&D.

Which specialties are involved in the integration of ultrasone sensors?

With the support of Pil, Sentech integrates customer-specific ultrasonic sensors. Here, Pil has the ultrasonic production expertise in house and we assist you with our knowledge of engineering, design and integration. This partnership enables you to easily put your specific sensor solution into your machine yourself.

When it comes to sensor technologies, you can never be an expert in everything. Based on your needs, our R&D Engineers research technologies that fit your application. Pil Sensoren provides support with their knowledge and experience in the area of ultrasonic technology.

Together with you, we search for a balance among quality, price, performance and lead time. We do this by going through process steps that are based on automotive quality. That’s how we — in collaboration with the right partners — develop and integrate the correct and reliable sensor solution for you.

Ultrasonic distance sensors suitable for harsh environments

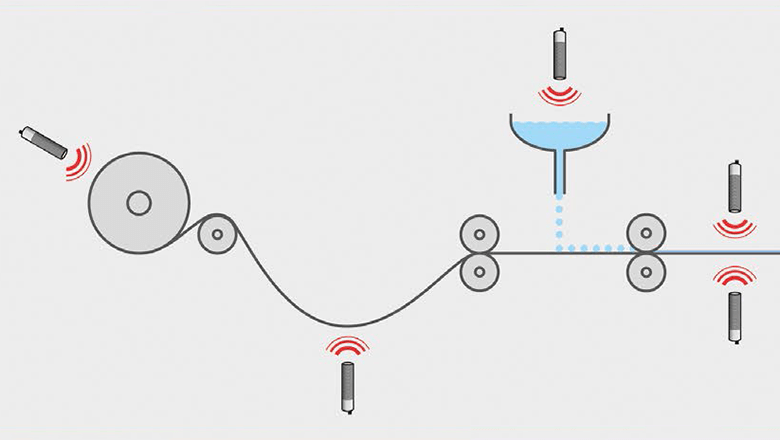

Ultrasonic technology measures distances using high-frequency sound waves. Sound is not sensitive to dust or moisture, which makes this distance sensor suitable for dusty and damp environments.

With their narrow sound cone, these sensors also effortlessly detect uneven surfaces and reflective fluid surfaces. Even glass and transparent films provide reliable measurements.

In which applications could ultrasonic sensors be the right solution?

-

Object detection in the Agro industry

In agricultural vehicles, ultrasonic sensors measure such factors as crop heights. The sensors’ high sealing to IP68 ensures that dust and moisture cannot influence the measurement results. That makes this technology the right distance sensor in agricultural applications. -

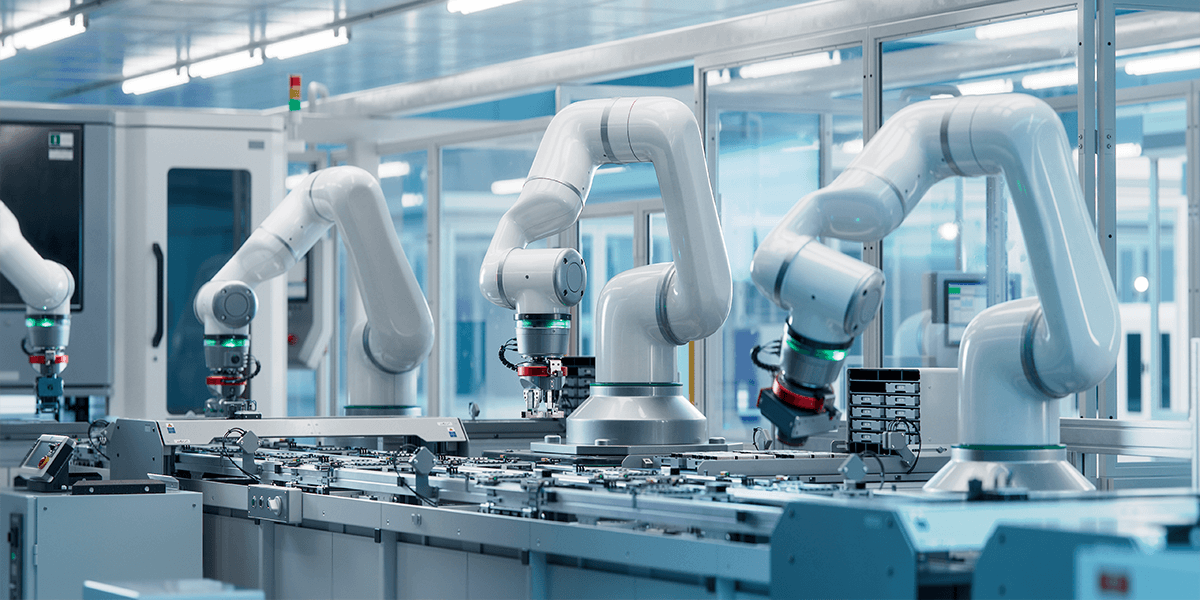

Unrolling detection in machines

You often see ultrasonic sensors in machines such as those used to unroll paper, film or textile rolls. A distance sensor detects all materials, even transparent film. -

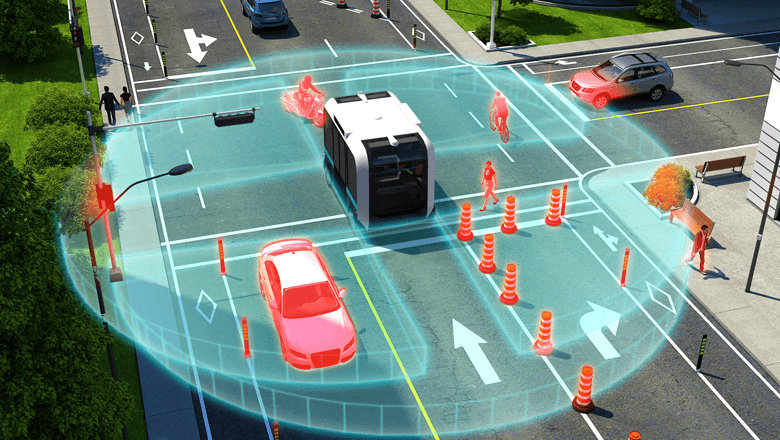

Distance measurement and collision detection in AGVs

Ultrasonic technology is a solution for collision avoidance in Automated Guided Vehicles (AGVs). Because ultrasonic sensors detect all materials and are not sensitive to moisture and dust, this technology is a safe solution.

Who is Pil Sensoren?

Pil Sensoren develops and produces ultrasonic sensors. You’ll find their distance sensors in industrial automation and in monitoring and automotive applications. Originally a German company, this sensor manufacturer is currently active worldwide.

Pil has developed many of their sensors in collaboration with clients. Through innovation, their assortment continues to grow. For example, they have integrated ultrasonic distance sensors with analog and switch outputs in the housings of photo-electronic controls.

See more sensor technologies that are right for your application

OK, so you’re looking for a distance sensor for your application. Don’t just focus on one technology; compare technologies. Besides ultrasonic sensors, you can also measure distances using lasers and radar.

Radar works based on a high-frequency transmission. Just like ultrasonic sensors, radar sensors are suitable for applications in harsh environments.

How does distance measuring work with radar technology? Learn whether it is right for your application.